- DL manuals

- Woodstock

- Lathe

- SHOP FOX W1758

- Owner's Manual

Woodstock SHOP FOX W1758 Owner's Manual

Phone: (360) 734-3482 • Online Technical Support: tech-support@shopfox.biz

COPYRIGHT © JUNE, 2007 BY WOODSTOCK INTERNATIONAL, INC., REVISED MARCH, 2013 (TS)

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE OR FORM WITHOUT

THE WRITTEN APPROVAL OF WOODSTOCK INTERNATIONAL, INC. (FOR MODELS MANUFACTURED SINCE 4/10)

Printed in China

OWNER'S MANUAL

MODEL W1758

VARIABLE SPEED WOOD LATHE

WITH DIGITAL READOUT

#9397TS

Summary of SHOP FOX W1758

Page 1

Phone: (360) 734-3482 • online technical support: tech-support@shopfox.Biz copyright © june, 2007 by woodstock international, inc., revised march, 2013 (ts) warning: no portion of this manual may be reproduced in any shape or form without the written approval of woodstock international, inc. (for mo...

Page 2

This manual provides critical safety instructions on the proper setup, operation, maintenance, and service of this machine/tool. Save this document, refer to it often, and use it to instruct other operators. Failure to read, understand and follow the instructions in this manual may result in fire or...

Page 3: Contents

Se t u p el ec tr ic a l m a inte n a n ce se rv ic e pa rt s o pe r atio ns sa fe t y in tr o du ct io n use the quick guide page labels to search out information fast! Contents introduction ...................................... 2 woodstock technical support .................. 2 safety ..............

Page 4: Introduction

-2- w1758 owner's manual (mfg. Since 4/10) in tr o du ct io n woodstock technical support this machine has been specially designed to provide many years of trouble-free service. Close attention to detail, ruggedly built parts and a rigid quality control program assure safe and reliable operation. Wo...

Page 5

-3- w1758 owner's manual (mfg. Since 4/10) in tr o du ct io n model w1758 machine specifications, page 1 of 3 model w1758 shop fox ® 16" x 46" wood lathe with stand and dro product dimensions weight.........................................................................................................

Page 6

-4- w1758 owner's manual (mfg. Since 4/10) in tr o du ct io n model w1758 machine specifications, page 2 of 3 motors main type......................................................................... Tefc capacitor-start induction horsepower..............................................................

Page 7: Controls And Features

-5- w1758 owner's manual (mfg. Since 4/10) in tr o du ct io n controls and features a. Motor b. Digital readout c. Spindle d. Spur center e. Speed control lever f. Tool rest g. Tool rest base with extension h. Tailstock locking lever i. Live center a h p q r i j k m n o b c d e f g l j. Quill lockin...

Page 8: Notice

-6- w1758 owner's manual (mfg. Since 4/10) sa fe t y indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury. Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. Indicates a potentially hazardous...

Page 9

-7- w1758 owner's manual (mfg. Since 4/10) sa fe t y wearing proper apparel. Do not wear clothing, apparel, or jewelry that can become entangled in moving parts. Always tie back or cover long hair. Wear non-slip footwear to avoid accidental slips, which could cause loss of workpiece control. Hazardo...

Page 10

-8- w1758 owner's manual (mfg. Since 4/10) sa fe t y integrity of stock. Verify each workpiece is free of knots, splits, nails, or foreign material to ensure it can safely rotate on spindle without breaking apart or causing turning tool kickback. Workpiece preparation. Before mounting, cut off waste...

Page 11: Electrical

-9- w1758 owner's manual (mfg. Since 4/10) el ec tr ic a l do not work on your electrical system if you are unsure about electrical codes and wiring! Seek assistance from a qualified electrician. Ignoring this warning can cause electrocution, fire, or machine damage. Electrical 110v operation the mo...

Page 12: Unpacking

-10- w1758 owner's manual (mfg. Since 4/10) se tu p this machine has been carefully packaged for safe trans- portation. If you notice the machine has been damaged during shipping, please contact your authorized shop fox dealer immediately. Unpacking setup the following is a description of the main c...

Page 13: Cleaning Machine

-11- w1758 owner's manual (mfg. Since 4/10) se tu p • floor load: this lathe distributes a heavy load in a small footprint. Some residential floors may require additional bracing to support both machine and operator. • working clearances: consider existing and anticipated needs, size of material to ...

Page 14: Mounting To Shop Floor

-12- w1758 owner's manual (mfg. Since 4/10) se tu p although not required, we recommend that you mount your new machine to the floor. Because this is an optional step and floor materials may vary, floor mounting hard- ware is not included. Generally, you can either bolt your machine to the floor or ...

Page 15

-13- w1758 owner's manual (mfg. Since 4/10) se tu p 3. Using the 6mm hex wrench, secure the lathe to the legs with the eight cap screws and lock washers, as shown in figure 8. 4. Install the handle into the tool rest, as shown in figure 9. 5. Align the quill keyway with the entry hole of the quill l...

Page 16: Test Run

-14- w1758 owner's manual (mfg. Since 4/10) se tu p once the assembly is complete, test run your machine to make sure it runs properly and is ready for regular opera- tion. The test run consists of verifying the following: 1) the motor powers up and runs correctly, and 2) the switch disabling mechan...

Page 17: Operations

-15- w1758 owner's manual (mfg. Since 4/10) o pe r atio ns operations general this lathe will perform many types of operations that are beyond the scope of this manual. Many of these operations can be dangerous or deadly if performed incorrectly. The instructions in this section are written with the...

Page 18: Adjusting Headstock

-16- w1758 owner's manual (mfg. Since 4/10) o pe r atio ns adjusting headstock the model w1758 headstock can be positioned anywhere along the bed and swiveled 360°. To position the headstock along the length of the lathe bed, do these steps: 1. Disconnect the lathe from power! 2. Loosen the headstoc...

Page 19: Adjusting Tailstock

-17- w1758 owner's manual (mfg. Since 4/10) o pe r atio ns adjusting tailstock the tailstock is equipped with a cam-action clamping sys- tem to secure it to the lathe bed. When the locking lever is tightened, a locking plate lifts up underneath the bed and secures the tailstock in place. To position...

Page 20: Installing/removing

-18- w1758 owner's manual (mfg. Since 4/10) o pe r atio ns installing/removing headstock center the included spur center installs into the headstock spin- dle with an mt#2 tapered fit. To install the headstock spur center, do these steps: 1. Disconnect the lathe from power! 2. Move the tailstock and...

Page 21: Installing/removing

-19- w1758 owner's manual (mfg. Since 4/10) o pe r atio ns installing/removing tailstock center the included live center installs into the tailstock quill with an mt#2 tapered fit. To install the tailstock live center, do these steps: 1. Move the tailstock to a safe working distance away from the to...

Page 22: Installing/removing

-20- w1758 owner's manual (mfg. Since 4/10) o pe r atio ns installing/removing faceplate the faceplate is used for removing material from the face of the workpiece, such as in hollowing operations. The faceplate can be installed only if the center has been removed from the headstock spindle. To inst...

Page 23: Selecting Turning Tools

-21- w1758 owner's manual (mfg. Since 4/10) o pe r atio ns selecting turning tools lathe chisels come in a variety of shapes and sizes, and usually fall into five major categories. See figures 22–25 for some examples. Gouges: mainly used for rough cutting, detail cutting, and cove profiles. The roug...

Page 24: Spindle Turning

-22- w1758 owner's manual (mfg. Since 4/10) o pe r atio ns spindle turning spindle turning is the operation performed when a workpiece is mounted between the headstock and tailstock centers (see figure 26). Figure 26. Typical spindle turning operation. Workpiece workpiece center pencil lines marked ...

Page 25

-23- w1758 owner's manual (mfg. Since 4/10) o pe r atio ns 8. Install the live center into the tailstock quill, and lock the quill in place with the quill locking lever (refer to installing tailstock center on page 19 for instructions). 9. Slide the tailstock toward the workpiece until the point of ...

Page 26: Faceplate Turning

-24- w1758 owner's manual (mfg. Since 4/10) o pe r atio ns faceplate turning faceplate turning is when a workpiece is mounted to the faceplate that, in turn, is secured to the headstock spin- dle. This type of turning is usually done with open-faced workpieces like bowls or plates (see figure 30). T...

Page 27: Outboard Turning

-25- w1758 owner's manual (mfg. Since 4/10) o pe r atio ns outboard turning outboard turning is a variation of faceplate turning and is usually done when stock diameter is greater than 12". For the size of the model w1758 and its minimum turn- ing speed, we recommend not exceeding a maximum workpiec...

Page 28: Accessories

-26- w1758 owner's manual (mfg. Since 4/10) o pe r atio ns accessories wood lathe accessories the following wood lathe accessories may be available through your local woodstock international inc. Dealer. If you do not have a dealer in your area, these products are also available through online deal-...

Page 29: Maintenance

-27- w1758 owner's manual (mfg. Since 4/10) m a inte n a n ce maintenance lubrication since all bearings for the model w1758 are sealed and permanently lubricated, simply leave them alone until they need to be replaced. Do not lubricate them. Wipe a lightly oiled shop rag on the outside of the heads...

Page 30: Service

-28- w1758 owner's manual (mfg. Since 4/10) se rv ic e service this section covers the most common service adjustments or procedures that may need to be made during the life of your machine. If you require additional machine service not included in this section, please contact woodstock internationa...

Page 31

-29- w1758 owner's manual (mfg. Since 4/10) se rv ic e electrical components & wiring diagram neutral hot ground 110 vac nema 5-15 plug (as recommended) paddle switch digital readout spindle speed sensor motor bk bk bk bk bk wt wt wt wt gr gr gr rd capacitor 100mfd 250vac.

Page 32: Troubleshooting

-30- w1758 owner's manual (mfg. Since 4/10) se rv ic e troubleshooting this section covers the most common problems and corrections with this type of machine. Warning! Do not make any adjustments until power is disconnected and moving parts have come to a complete stop! Problem possible cause correc...

Page 33

-31- w1758 owner's manual (mfg. Since 4/10) pa rt s problem possible cause corrective action bad surface finish. 1. Wrong spindle speed. 2. Dull chisel or wrong chisel being used for operation. 1. Use trail-and-error to find better spindle speed. 2. Sharpen chisel or try a different chisel. Tailstoc...

Page 34: Parts

-32- w1758 owner's manual (mfg. Since 4/10) pa rt s 101 102 103 104 105v2 105-1v2 105-2v2 105-4v2 105-5v2 105-6v2 106 107 108 109 110 111 112 113 114 115 115-1 115-2 115-4 116 116-1 117 118 119 120 121 122 123 124 125 126 127 128 129 129-1 130 131 132 133 134 135 136 137 138 139 140 141 142 143 144 ...

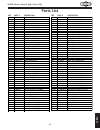

Page 35: Parts List

-33- w1758 owner's manual (mfg. Since 4/10) pa rt s parts list ref part # description ref part # description 101 xps05m phlp hd scr m5-.8 x 8 140 xpr58m ext retaining ring 24mm 102 x1758102 motor cover 141 x1758141 speed change label 103 xpb26m hex bolt m8-1.25 x 30 142 x1758142 speed control lever ...

Page 36: Label Placement

-34- w1758 owner's manual (mfg. Since 4/10) pa rt s label placement safety labels warn about machine hazards and how to prevent machine damage or injury. The owner of this machine must maintain the original location and readability of all labels on this machine. If any label is removed or becomes un...

Page 37: Warranty Registration

W1758 owner's manual (mfg. Since 4/10) cut along dotted line name ___________________________________________________________________________________ street __________________________________________________________________________________ city _________________________ state _______________________...

Page 38

Tape along edges--please do not staple fold along dotted line fold along dotted line woodstock international inc. P.O. Box 2309 bellingham, wa 98227-2309 place stamp here.

Page 39: Warranty

Warranty woodstock international, inc. Warrants all shop fox machinery to be free of defects from workman- ship and materials for a period of two years from the date of original purchase by the original owner. This warranty does not apply to defects due directly or indirectly to misuse, abuse, negli...

Page 40

High quality machines and tools woodstock international, inc. Carries thousands of products designed to meet the needs of today's woodworkers and metalworkers. Ask your dealer about these fine products:.