- DL manuals

- Woodstock

- Lathe

- SHOP FOX W1752 s

- Owner's Manual

Woodstock SHOP FOX W1752 s Owner's Manual

OWNER'S MANUAL

(FOR MODELS MANUFACTURED SINCE 1/07)

MODEL W1752

MINI WOOD LATHE

Phone: (360) 734-3482 • Online Technical Support: tech-support@shopfox.biz

COPYRIGHT © JANUARY, 2007 BY WOODSTOCK INTERNATIONAL, INC. REVISED AUGUST, 2010 (TR)

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE OR FORM WITHOUT

THE WRITTEN APPROVAL OF WOODSTOCK INTERNATIONAL, INC.

Printed in China

#8952BL

Summary of SHOP FOX W1752 s

Page 1

Owner's manual (for models manufactured since 1/07) model w1752 mini wood lathe phone: (360) 734-3482 • online technical support: tech-support@shopfox.Biz copyright © january, 2007 by woodstock international, inc. Revised august, 2010 (tr) warning: no portion of this manual may be reproduced in any ...

Page 2

This manual provides critical safety instructions on the proper setup, operation, maintenance and service of this machine/equipment. Failure to read, understand and follow the instructions given in this manual may result in serious personal injury, including amputation, electrocution or death. The o...

Page 3: Contents

Se t u p el ec tr ic a l m a inte n a n ce se rv ic e pa rt s o pe r atio ns sa fe t y in tr o du ct io n use the quick guide page labels to search out information fast! Contents introduction ...................................... 2 woodstock technical support .................. 2 safety ..............

Page 4: Introduction

-2- w1752 owner's manual (mfg. 1/07+) in tr o du ct io n woodstock technical support your new shop fox ® mini wood lathe has been specially designed to provide many years of trouble- free service. Close attention to detail, ruggedly built parts and a rigid quality control program assure safe and rel...

Page 5: Machine

-3- w1752 owner's manual (mfg. 1/07+) in tr o du ct io n phone #: (360) 734-3482 • online tech support: tech-support@shopfox.Biz • web: www.Shopfox.Biz machine specifications model w1752 mini wood lathe motor type ................................................................................. Capa...

Page 6

-4- w1752 owner's manual (mfg. 1/07+) in tr o du ct io n main specifications swing over bed ................................................................................... 10" swing over tool rest ........................................................................... 7 1 / 2 " distance betw...

Page 7: Controls And Features

-5- w1752 owner's manual (mfg. 1/07+) in tr o du ct io n controls and features figure 1. W1752 controls and features. A. Belt tension lock knob b. Belt cover lock handle c. Belt cover d. Headstock e. Faceplate f. Tool rest base g. Tool rest h. Tool rest lock handle i. Tool rest release lever j. Tail...

Page 8: Safety

-6- w1752 owner's manual (mfg. 1/07+) sa fe t y safety read manual before operating machine. Failure to follow instructions below will result in personal injury. Standard safety instructions 1. Read through the entire manual before starting machinery. Machinery presents serious injury hazards to unt...

Page 9

-7- w1752 owner's manual (mfg. 1/07+) sa fe t y 10. Never leave when machine is running. Turn power off and allow all moving parts to come to a complete stop before leaving machine unattended. 11. Do not use in dangerous environments. Do not use machinery in damp, wet locations, or where any flammab...

Page 10

-8- w1752 owner's manual (mfg. 1/07+) sa fe t y additional safety for wood lathes use this and other machinery with caution and respect. Always consider safety first, as it applies to your individual working conditions. No list of safety guidelines can be complete—every shop environment is different...

Page 11

-9- w1752 owner's manual (mfg. 1/07+) sa fe t y 13. Faceplate turning. When faceplate turning, use lathe chisels on the downward spinning side of the workpiece only. 14. Sanding/polishing. Remove the tool rest when performing sanding or polishing operations on the rotating spindle. 15. Material remo...

Page 12: Electrical

-10- w1752 owner's manual (mfg. 1/07+) el ec tr ic a l do not work on your electrical system if you are unsure about electrical codes and wiring! Seek assistance from a qualified electrician. Ignoring this warning can cause electrocution, fire, or machine damage. Electrical we do not recommend using...

Page 13: Unpacking

-11- w1752 owner's manual (mfg. 1/07+) se t u p the shop fox ® model w1752 has been carefully pack- aged for safe transporting. If you notice the machine has been damaged, please contact your authorized shop fox ® dealer immediately. Unplug-power cord before you do any assembly or adjustment tasks! ...

Page 14: Cleaning Machine

-12- w1752 owner's manual (mfg. 1/07+) se t u p • floor load: some workbenches may require additional reinforcement to support both the machine and the operator. Make sure you take these precautions. • working clearances: consider existing and anticipated needs, size of material to be processed thro...

Page 15: Assembly

-13- w1752 owner's manual (mfg. 1/07+) se t u p to install the tool rest, do these steps: 1. Turn the release lever on the tool rest base so it does not interfere with assembly. 2. Thread the tool rest lock handles into the tool rest base ( figure 4) until the threaded ends of the handles are flush ...

Page 16: Test Run

-14- w1752 owner's manual (mfg. 1/07+) se t u p projectiles thrown from the machine could cause serious eye injury. Wear safety glasses during assembly and operation. Loose hair and clothing could get caught in machinery and cause serious personal injury. Keep loose clothing rolled up and long hair ...

Page 17: Operations

-15- w1752 owner's manual (mfg. 1/07+) o pe r atio ns operations general the model w1752 will perform many types of operations that are beyond the scope of this manual. Many of these operations can be dangerous or deadly if performed incor- rectly. The instructions in this section are written with t...

Page 18: Changing Speeds

-16- w1752 owner's manual (mfg. 1/07+) o pe r atio ns changing speeds to change speeds, the belt in the headstock must be repositioned. A chart on the pulley cover shows the belt positions needed to make the lathe run at the desired speed. To change speeds, do these steps: 1. Loosen the lock handle,...

Page 19: Adjusting Tool Rest

-17- w1752 owner's manual (mfg. 1/07+) o pe r atio ns adjusting tool rest the tool rest is equipped with a cam-action clamping system to secure it to the lathe bed. When the lever is engaged, a locking plate lifts up and secures the tool rest base to the bed. To position the tool rest base along the...

Page 20: Installing/removing

-18- w1752 owner's manual (mfg. 1/07+) o pe r atio ns figure 11. Removing spur center using knock out bar. To remove the spur center with the knock-out bar, do these steps: 1. Unplug lathe from power! 2. Hold a clean rag under the spindle or wear a glove to catch the center when you remove it. 3. In...

Page 21: Installing/removing

-19- w1752 owner's manual (mfg. 1/07+) o pe r atio ns installing/removing faceplate the faceplate can be installed only if the spur center has been removed from the headstock spindle. The knock-out bar is included with the lathe for installing and removing the faceplate. To install the faceplate, do...

Page 22: Selecting Turning Tools

-20- w1752 owner's manual (mfg. 1/07+) o pe r atio ns figure 14. Gouge. Selecting turning tools lathe tools come in a variety of shapes and sizes and usually fall into five major categories. • gouges—mainly used for rough cutting, detail cut- ting, and cove profiles. The rough gouge is a hol- low, d...

Page 23: Spindle Turning

-21- w1752 owner's manual (mfg. 1/07+) o pe r atio ns spindle turning spindle turning ( figure 18) is the operation performed when a workpiece is mounted between the headstock and the tailstock. To set up a spindle turning operation, do these steps: 1. Mark both ends of your workpiece by drawing dia...

Page 24

-22- w1752 owner's manual (mfg. 1/07+) o pe r atio ns 6. With the workpiece still attached, insert the spur center into the headstock spindle. 7. With the live center installed in the tailstock, slide the tailstock toward the workpiece until the live center touches the workpiece centerpoint, then lo...

Page 25: Faceplate Turning

-23- w1752 owner's manual (mfg. 1/07+) o pe r atio ns faceplate turning faceplate turning ( figure 22) is when a workpiece is mounted to the 3" faceplate, which is mounted to the headstock spindle. This type of turning is usually done with open-faced workpieces like bowls. To mount your workpiece to...

Page 26: Sanding/finishing

-24- w1752 owner's manual (mfg. 1/07+) o pe r atio ns figure 25. Typical sanding operation. Sanding/finishing after turning, the workpiece can be sanded, as shown in figure 25, and finished (in the same manner) before removing it from the lathe. Sandpaper workpiece entanglement hazard! Wrapping the ...

Page 27: Accessories

-25- w1752 owner's manual (mfg. 1/07+) o pe r atio ns accessories lathe accessories the following lathe accessories may be available through your local woodstock international inc. Dealer. If you do not have a dealer in your area, these products are also available through online dealers. Please call...

Page 28: Maintenance

-26- w1752 owner's manual (mfg. 1/07+) m a inte n a n ce maintenance lubrication lubricate the locations shown in figure 26 with light machine oil. Regular periodic maintenance on your shop fox ® model w1752 will ensure its optimum performance. Make a habit of inspecting your machine each time you u...

Page 29: Service

-27- w1752 owner's manual (mfg. 1/07+) se rv ic e service troubleshooting this section covers the most common problems and corrections with this type of machine. Warning! Do not make any adjustments until power is disconnected and moving parts have come to a complete stop! Problem possible cause cor...

Page 30

-28- w1752 owner's manual (mfg. 1/07+) se rv ic e problem possible cause corrective action vibration noise while machine is running; noise remains constant when speed is changed. 1. Dented fan cover on motor. 1. Replace or adjust fan cover. Inspect motor fan and replace if damaged. Excessive vibrati...

Page 31: Wiring Diagram W1752

-29- w1752 owner's manual (mfg. 1/07+) se rv ic e wiring diagram w1752 5-15 plug white neutral black hot green ground paddle switch (viewed from behind) 110 vac motor ground run capacitor 25mfd 250vac bk rd rd rd black white green red color key bk wt gn rd bk bk bk bk wt wt wt wt gn gn gn gn figure ...

Page 32: Parts

-30- w1752 owner's manual (mfg. 1/07+) pa rt s parts 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 1 2 3 4 5 6 7 8 9 10 11 11 12 13 14 15 16-1 16-2 16-3 16-4 16 17 18 19 20 21-1 21 22 23 24 25 26 27-1 27-2...

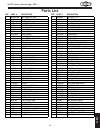

Page 33: Parts List

-31- w1752 owner's manual (mfg. 1/07+) pa rt s parts list ref part # description ref part # description 1 xpaw02.5m hex wrench 2.5mm 37 xprp61m roll pin 3 x 12 2 x1752002 tool rest release lever 38 x1752038 belt tension lock knob 3 x1752003 lever knob 39 x1752039 thumb screw m5-.8 x 15 4 x1752004 ec...

Page 34: Label Placement

-32- w1752 owner's manual (mfg. 1/07+) pa rt s label placement safety labels warn about machine hazards and how to prevent machine damage or injury. The owner of this machine must maintain the original location and readability of all labels on this machine. If any label is removed or becomes unreada...

Page 35: Notes

Notes.

Page 36: Notes

Notes.

Page 37

W1752 owner's manual (mfg. 1/07+).

Page 38

Tape along edges--please do not staple fold along dotted line fold along dotted line woodstock international inc. P.O. Box 2309 bellingham, wa 98227-2309 place stamp here.

Page 39: Warranty

Warranty woodstock international, inc. Warrants all shop fox machinery to be free of defects from workmanship and materials for a period of two years from the date of original purchase by the original owner. This warranty does not apply to defects due directly or indirectly to misuse, abuse, neglige...

Page 40

High quality machines and tools woodstock international, inc. Carries thousands of products designed to meet the needs of today's woodworkers and metalworkers. Ask your dealer about these fine products:.