- DL manuals

- Woodstock

- Power Tool

- H0626

- Instruction Manual

Woodstock H0626 Instruction Manual

INSTRUCTION MANUAL

MODEL W1668

13

1

⁄

4

" Oscillating Drill Press

Phone: 1-800-840-8420 • On-Line Technical Support: tech-support@woodstockint.com

COPYRIGHT © 2000 BY WOODSTOCK INTERNATIONAL, INC.

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE OR FORM WITHOUT

THE WRITTEN APPROVAL OF WOODSTOCK INTERNATIONAL, INC.

Printed in China

Summary of H0626

Page 1

Instruction manual model w1668 13 1 ⁄ 4 " oscillating drill press phone: 1-800-840-8420 • on-line technical support: tech-support@woodstockint.Com copyright © 2000 by woodstock international, inc. Warning: no portion of this manual may be reproduced in any shape or form without the written approval ...

Page 2: Table of Contents

- 1 - table of contents page 1. Introduction about your new drill press ......................................................2 woodstock service and support ................................................2 warranty and returns ..............................................................3 machine...

Page 3: Introduction

- 2 - introduction about your new drill press this new shop fox ® oscillating drill press has been specially designed by woodstock international, inc. To provide many years of trouble free service. Close attention to detail, ruggedly built parts and a rigid quality control program assure safe and re...

Page 4: Warranty and Returns

- 3 - warranty and returns woodstock international, inc. Warrants all shop fox ® machinery to be free of defects from workman- ship and materials for a period of 2 years from the date of original purchase by the original owner. This warranty does not apply to defects due directly or indirectly to mi...

Page 5: Result In Personal Injury

- 4 - read manual before operating machine failure to follow instructions below will result in personal injury safety first! 1. Thoroughly read the instruction manual before operating your machine. Learn the applications, limitations and potential hazards of this machine. Keep manual in a safe, conv...

Page 6

1. Always operate your drill press at speeds that are appropriate for the drill bit size and the mate- rial that you are drilling. 2. Feed the drill bit evenly into the workpiece. Back the bit out of deep holes and clear the chips with a brush after you have turned the machine off. 3. Make sure the ...

Page 7: 110V Operation

- 6 - 110v operation electrical requirements when it is necessary to use an extension cord, use the following guidelines: •use cords rated for hard service •never exceed a length of 100 feet •use cords with 14 ga. Wire or bigger •insure cord has a ground wire and pin •do not use cords in need of rep...

Page 8: Avoiding Potential Injuries

Avoiding potential injuries - 7 - figure 2. Never drill, holding workpiece by hand. Figure 3. Keep fingers away from spinning tool. Fig. 4. Remove switch safety key when not in use. Figure 5. Remove handles when using oscillating mode..

Page 9: Assembly Instructions

- 8 - figure 6. Components laid out for identification. The following is a description of the components shipped with the shop fox ® w1668 oscillating drill press. It is recommended that the components be laid out in a similar fashion to those in figure 6. This will help in identification before beg...

Page 10: Assembly

- 9 - assembly while the main components of the shop fox ® w1668 oscillating drill press are assembled at the factory, some assembly is required. The following is the recommended sequence best suited for final assembly. Tools required: you will need a 10mm, 12mm and 14mm open end wrench, a flat tipp...

Page 11: Table Support

- 10 - figure 11. Lock shoe inserted into table bracket. Figure 9. Insert the pinion gear from the inside. Figure 10. Align setscrew with flat on pinion. Table support 1. Thread the 12mm table lock handle 3 turns into the table support bracket. 2. Insert the pinion into the hole on the side of the t...

Page 12: Table Support, Cont.

- 11 - figure 12. Hold rack in position while installing. Figure 13. Inside bevel in the correct position. Figure 14. Lock shoe in place and secured. Table support, cont. 4. Examine the rack and note that the gear teeth extend further on one end than the other. Insert the rack into the table support...

Page 13: Headstock

- 12 - headstock 1. The bottom of the headstock has a pocket for inserting the column. Position the pock- et over the column, as in figure 15. Allow the headstock to slide down until it stops (approximately 3 1 ⁄ 2 "). 2. Align the headstock directly over the foot of the base by using a plumb bob. L...

Page 14: Handles

- 13 - handles three handles are supplied with your new oscillating drill press. Thread them into the hub as in figure 20. Figure 20. Spindle handle installation. Drill chuck figure 19. Securing drill chuck with screw. Figure 18. Jaws adjusted inside chuck body. The drill chuck is attached to the dr...

Page 15: Speed Change

- 14 - speed change adjustments unplug the drill press before changing speeds. The oscillating drill press has 12 speeds ranging from 250 to 3050 rpm. There is a speed chart located under the belt guard and one on the fol- lowing page. Refer to the speed chart while reading these instructions. 1. Lo...

Page 16: Spindle Adjustments

- 15 - spindle adjustments your new drill press comes fitted with a depth stop for use when drilling. Follow the instruc- tions below for use. 1. Loosen the depth collar lock knob. Figure 24. 2. Rotate the depth collar to the desired depth indicated by the scale on the collar. Secure the collar with...

Page 17: Oscillating Feature

- 16 - oscillating feature one of the great features of the w1668 drill press is its capability for oscillating sanding. The drill press can be converted from drilling opera- tions to sanding operations in just a few steps. 1. Unplug the drill press and remove the spindle handles. 2. Install the rou...

Page 18: Table Adjustments

- 17 - table adjustments the table can be adjusted to accommodate height of materials to be sanded or drilled. To adjust: 1. Loosen the table support bracket lock knob. Turn the table hand crank to raise or lower the table. Figure 27. 2. The table can be adjusted out of the way so the base of the dr...

Page 19: Operations

Always wear safety glass- es when operating drill press. Failure to comply may result in serious per- sonal injury. - 18 - operations once assembly is complete and adjustments are done to your satisfaction, you are ready to test run the machine. Make sure the starting switch is off. The paddle is do...

Page 20: Drill Changes

Installing the sanding drum spindle is identical to installing a drill bit. However, it is important to install the paper and drum before installing the spindle into the drill chuck. See your local retailer for drums and paper. - 19 - care must be taken to secure the bit firmly in the drill chuck. W...

Page 21: Maintenance

- 20 - maintenance lubrication since all bearings are shielded and permanently lubricated, simply leave them alone until they need to be replaced. Do not lubricate them. For other items on this machine, such as the quill, table and column, an occasional shot of light machine oil is all that is neces...

Page 22: Closure

- 21 - the following pages contain general machine data, parts diagrams/lists and warranty/return information for your shop fox ® model w1668 drill press. If you need parts or help in assembling your machine, or if you need operational informa- tion, we encourage you to call our service department. ...

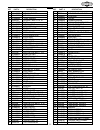

Page 24

- 23 - 55 xpb07m hex bolt m8-1.25 x 25 56 xpb09m hex bolt m8-1.25 x 20 57 x1668057 push rod 58 x1668058 spring 59 x1668059 rubber washer 60 x1668060 oscillating mechanism 61 x1668061 round drive belt 62 x1668062 pulley cover 63 xp6203 ball bearing 6203 64 x1668064 collar 65 x1668065 internal spline ...

Page 25: Notes:

- 24 - notes:.

Page 26: Warranty Card

Cut along dotted line 10. What stationary woodworking tools do you own? Check all that apply. ___air compressor ___panel saw ___band saw ___planer ___drill press ___power feeder ___drum sander ___radial arm saw ___dust collector ___shaper ___horizontal boring machine ___spindle sander ___jointer ___...

Page 27

Tape along edges--please do not staple fold along dotted line fold along dotted line woodstock international, inc. P.O. Box 2309 bellingham, wa 98227-2309 place stamp here.