- DL manuals

- Macco

- Coffee Maker

- ILC-200

- Technical Instructions

Macco ILC-200 Technical Instructions

Summary of ILC-200

Page 1

Techni instructions ilc -200 lb-05061 edition ish pag.1 echnical instructions 5061-02.En edition october 2013 en eng 27/03/2014 www. Ebg.Com.Au.

Page 2

Pag.2 27/03/2014 table of contents general characteristics ..................................................................................................................................................................................... 5 test report on energy consumption ..........................

Page 3

Pag.3 27/03/2014 introduction and general notes thoroughly read the instructions contained in this booklet because it gives important information regarding safety for installation, use and maintenance. Keep this booklet in a safe and accessible place for further consultation. This machine must be us...

Page 4

Pag.4 27/03/2014 1. Essential operational requirements 1.1 the machine shall be supplied with water for human consumption, in compliance with the laws in force where the installation is performed. The installer shall check with the owner or manager of the machine if the water complies with the requi...

Page 5

Pag.5 27/03/2014 general characteristics machines in self configuration (see exploded view manual for code number) functions are absent or disabled by software: • steam wand: absent • extra milk function by pushing the cappuccino/latte dose key: disabled by sw • function to stop the dose delivery by...

Page 6

Pag.6 27/03/2014 test report on energy consumption machine type: ilc-200 coffee boiler 1.0 litre heating element 1.8 kw (single phase) steam boiler 1.0 litre heating element 1.2 kw (single phase) machine load 3,15 kw environment temperature: 22°c measurement 1. Heat up phase to reach operational cof...

Page 7

Pag.7 27/03/2014 machine keypad key reference function 1 exit ( edit )/ espresso 2 ins ( insert blank ) / black coffee 3 del ( delete character ) / cappuccino 4 scroll / latte macchiato 5 - / choco 6 + / mocha 7 enter 8 on-off / esc 9 steam 10 hot water 11 info 12 shift /clean exit del - enter ins s...

Page 8

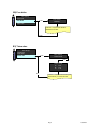

Pag.8 27/03/2014 electric - hydraulic connection h2o in ( 1-6 bar ) h2o out water softner water filtre.

Page 9

Pag.9 27/03/2014 starting up warning : all parameters that concern the steam boiler will not be displayed in ilc-200 easy machines. After having connected the machine to the water and electric networks, turn the switch on (see diagram). The display shows: language english use: + / - keys to select t...

Page 10

Pag.10 27/03/2014 press the key n°8 to switch on the machine . , the display shows: filling - up steam boiler during this stage the steam boiler is being filled up. Warning: the solenoid valve of the steam nozzle automatically opens to release the air inside the boiler. When the steam boiler has bee...

Page 11

Pag.11 27/03/2014 select drink for machine configurations: self. The display shows: select drink alternated with the message: position the cup for machine configurations: waiters’ card the display shows: insert card for machine configurations: self + credit card the display shows: insert card for ma...

Page 12

Pag.12 27/03/2014 warning: a) for self with coin box configuration the selections doses are enabled only when the set-up temperature of both boilers ( coffee- steam ) have been reached. B) to switch on the machine on every type of self – configuration, press key n°8, the display shows: after insert ...

Page 13

Pag.13 27/03/2014 schematic summary of steam and coffee boiler heating phase heating element on temperature sensor ( please wait ) steam boiler heating element off on set-up ( select drink ) 0°c °c steam nozzle solenoid valve solenoid valve open on off solenoid valve close 50°c 95°c °c milk frother ...

Page 14

Pag.14 27/03/2014 access the main setting menus with password or smart-card a) access the main setting menus with password to enter the programming environments, a password is required which define the access rights to the different environments. The password must be composed with 5 numbers. To inse...

Page 15: Led

Pag.15 27/03/2014 b) access the main setting menus with smart card. ( only for machines with transponder installed ) to enter the programming environments , place one of the following smart cards above the proper reader with the led light on and the machine in off : - waiter smart card - roaster- sm...

Page 16

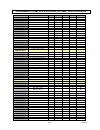

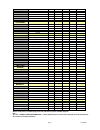

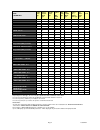

Pag.16 27/03/2014 programmable parameters in according with smart card or password waiter roaster owner service technician info - reset reard dose data douse counter a x x x x x douse counter b x x x x x system data group cleaning x x mixer cleaning x x milker cleaning x x grinder cycles x x water f...

Page 17

Pag.17 27/03/2014 gsm: sim card pin x x gsm: service phone number x x modem set-up parameters x x remote password x x user message x x x x x serial n° x x installation date x x system clock programming yy-mm-dd day hh:mm x° x° x° x x clock display x x x auto start -up x x x on - off x x x day off x ...

Page 18

Pag.18 27/03/2014 info-reset a1) read doses data ( doses counter a/b ) esc + -.

Page 19

Pag.19 27/03/2014 a2) read doses data ( reset doses counter a/b ).

Page 20

Pag.20 27/03/2014 b) info reset system data.

Page 21

Pag.21 27/03/2014 the following info are displayed only when the clock is programmed machine service xxxx yy - zzzz xxxx : indicates the n° of group cycles left. If the programmed n° of group cycles exceed the display shows: ( - xxxx ) yy : indicates the maintenance month zzzz : indicates the mainte...

Page 22

Pag.22 27/03/2014 doses programming please note : to access to the doses programming the machine must be at the set-up temperature. Press the key no 5 (-) and no 6 (+) to select the parameter and then press the key no 7 (enter) to confirm the selection. A) set doses esc + - coffee milk hot water dis...

Page 23

Pag.23 27/03/2014 press enter key to go to the next programming doses level . ( see following table ).

Page 24

Pag.24 27/03/2014 depending on the drink type, the necessary dose parameters will be activated to set the drink. Press the key n°7 (enter) to confirm the modification carried out and shift to the next level. Press the key n°6 (+) and no5 (-) to modify the level mode. Press the key n°8 ( esc) to retu...

Page 25

Pag.25 27/03/2014 b ) price set-up select - set doses - calibration - instant product calibration price set-up enter doses price bx xxxxxxxxx bx xxxxxxxxx bx xxxxxxxxx bx xxxxxxxxx price set-up - doses price - free drinks - token value b1) doses price price set-up - free drinks - token value doses p...

Page 26

Pag.26 27/03/2014 price set-up - doses price - token value free drinks b2) free drinks free drinks desable enter press the +/ - keys to insert enable or desable the free drink. Enter price set-up - doses price - free drinks token value b3) token value enter token value a : x.Xx b : x.Xx c : x.Xx pre...

Page 27

Pag.27 27/03/2014 c ) calibration ( grinder-milker ) steamed milk foamed milk grinder 1 press key b1 press key b2 press key b3 the calibration menù its useful to adjust the milker ( steamed milk-foamed milk ) and the grinders . To activate the milker and the grinder for max.5 seconds press b1- b2- b...

Page 28

Pag.28 27/03/2014 d) instant dispenser calibration enter instant product calibration mixer : a test: 1 enter instant product calibration mixer : a test: 1 yy. Sec / 50 ml. Yy.Sec. Indicates the time to delivery 50 ml. Of water. Enter instant product calibration mixer : a test: 2 yy. Sec / 50 ml. Yy....

Page 29

Pag.29 27/03/2014.

Page 30

Pag.30 27/03/2014 system manager press the key n°7 (enter) to confirm entering the desired environment. Press the key n° 8 (esc) to exit. Enter system manager - machine configuration - machine parameter - system clock programming - display regulation - service - smart card manager - change password ...

Page 31

Pag.31 27/03/2014 machine configuration enter machine configuration steam boiler enabled use: + / - keys to enable or disable the steam boiler. Machine configuration n. Of dispenser – mixer 1 use: + / - keys to select 0 - 1 -2 dispenser - mixer enter machine configuration water tank disable/enable u...

Page 32

Pag.32 27/03/2014 machine configuration sequential heater enabled use: + / - keys to enable or disable the sequential heater. Machine configuration milker enabled use: + / - keys to enable or disable the automatic milk frother. Enter machine configuration power cleaner disabled use: + / - keys to en...

Page 33

Pag.33 27/03/2014.

Page 34

Pag.34 27/03/2014 machine parameters please note : some of the following parameters may not be displayed depending to the machine configuration previously programmed. Language + / - enter english german french flemish italian japanese enter serial disable + / - i/o hartwall i/o 9600 rm5 coin box for...

Page 35

Pag.35 27/03/2014 please note : some of the following parameters may not be displayed depending to the machine configuration previously programmed. Rinse after milk dose enable disable + / - pause after milk 3 sec. 3 -10 sec. Waiting time milk dose a - b 15 min. 0 - 60 min. Additional milk 2 sec. 0 ...

Page 36

Lb-05061-02-en pag.36 27/03/2014.

Page 37

Lb-05061-02-en pag.37 27/03/2014 please note: for machines without gsm it is possible to carry out a local data download by setting the serial number and the remote password only. ( for more information see the wizard manual )..

Page 38

Pag.38 27/03/2014 system clock set-up system clock programming yy - mm - dd day hh:mm -- / -- / -- --- / -- : -- press the key +/- to program the date ( yy-mm-dd) and the time ( day hh:mm ) enter clock display disable enable + / - the clock will not be dispayed auto start-up enter on off xx:xx xx:xx...

Page 39

Pag.39 27/03/2014 display regulation.

Page 40

Pag.40 27/03/2014 service system manager - machine configuration - machine parameters - system clock programming - display regulation - smart card manager - change password - group manual movements - test actuactors - boiler draining - alarm history - preset configuration data - usb/trasponder manag...

Page 41

Pag.41 27/03/2014 cycle cleaning alarm clean/rinse - cleaning time - group cleaning program - group auto rinsing - mixer cleaning program - mixer auto rinsing - milker cleaning program - milker auto rinsing cycle cleaning alarm variable value : + / - 0 - 1000 press the keys + / - to program after ho...

Page 42

Pag.42 27/03/2014.

Page 43

Pag.43 27/03/2014.

Page 44

Pag.44 27/03/2014.

Page 45

Pag.45 27/03/2014 smart card manager please note: a -the smart card manager is displayed only for coffee machine with transponder installed. B -to create a new card (technician – service – owner – roaster and waiter ) its necessary use an external pc tool..

Page 46

Pag.46 27/03/2014.

Page 47

Pag.47 27/03/2014 change password please note : if the turn on password is enabled , to turn on the machine is necessary insert the password. Key reference for password waiter roaster owner service technician waiter roaster x owner x x service x x x technician x x x x following password can be modif...

Page 48

Lb-05061-02-en pag.48 27/03/2014 group manual movements group manual movements higher motor xxx motor expeller lower motor xxx enter where: xxx indicates the pulses of the upper and lower motor. Press the key : n° 1 and n° 2 to move the upper piston n° 3 and n° 4 to move the expeller motor n° 5 and ...

Page 49

Pag.49 27/03/2014 test actuators system manager - machine configuration - machine parameters - system clock programming - display regulation - service - smart card manager - change password - group manual movements - boiler draining - alarm history - preset configuration data - usb/trasponder manage...

Page 50

Lb-05061-02-en pag.50 27/03/2014 1 1 3 3 5 5 7 7 2 2 4 6 4 6 esc esc Λ v esc - +.

Page 51

Pag.51 27/03/2014 mixer a enter esc mixer test a 0 keep pressed the + key to increase the speed of the mixer a motor . Keep pressed the – key to decrase the speed. 0 -100 % variable value + / - dispenser a enter dispenser test a 0 0 -100 % variable value + / - keep pressed the + key to increase the ...

Page 52

Lb-05061-02-en pag.52 27/03/2014 warning: a) you can activate more than one actuator at the same time. B) once a time-out of 5 seconds has elapsed, the activated actuators will be automatically interrupted. C) the “milk pump speed” parameter will be displayed only for machine with milk pump installe...

Page 53

Lb-05061-02-en pag.53 27/03/2014 boiler draining warning: a) after the boiler draining procedure, when the machine is turned back on, the boilers charge will be carried out according to the procedure described in the chapter “starting up procedure”..

Page 54

Lb-05061-02-en pag.54 27/03/2014 alarm history please note: a) the maximum alarm number the machine can save is 10. B) to reset the alarm data memory, carry out “preset configuration data” procedure. Press the n°16 enter key to return to the previous environment and/or exit alarm details alarm code ...

Page 55

Lb-05061-02-en pag.55 27/03/2014 preset parameters preset configuration service enter power off and power on enter after 5 second the display shows preset configuration please wait technician factory +/ - service warning : - for custom preset contact the essential brands group technical service. - w...

Page 56

Pag.56 27/03/2014 usb/trasponder manager using the usb key this function, can be used to load a configuration data ( setting machine) from a coffee machine to usb key , or to upload a customized gui for the display. The data saved on the usb key can be loaded to another coffee machine. You can choos...

Page 57

Pag.57 27/03/2014 enter one of the following passwords: - owner 2 2 2 2 2 - service - technician 3 3 3 3 3 ( for technician password contact the essential brands group technical service ). The display shows: gui up-to-date - (this function can be used to upload a customized gui) . Use the key no. 5 ...

Page 58

Pag.58 27/03/2014 load from setting machine to usb key insert file name file 1 > to scroll the character use the keys (+ / - ). Press enter key to confirm the selection. Use key b1 to skip at the end of the name. Use key b2 to delete a letter. Use key b3 to insert a space. After you selected the req...

Page 59

Pag.59 27/03/2014.

Page 60

Pag.60 27/03/2014 cleaning process abort if you want to interrupt the cleaning procedure for group or whisk or milk frother follow the procedure: ( only with the technician or service password ).

Page 61

Pag.61 27/03/2014 trouble shooting 1) n°10 time out pulses, upper piston motor. H. Motor puls 10 this alarm is visualised on display by code 10 causes: the upper motor encoder has not received pulses for 3 seconds, since the motor is not running result: the machine is switched off. Check the followi...

Page 62

Pag.62 27/03/2014 5) n° 15 alarm of too much coffee in the brewing chamber. Too much coffee 15 this alarm is visualised on display by code 15 causes: the upper piston has positioned itself where the wet seal of the piston gasket in the brewing chamber is not guaranteed. Result: the machine is switch...

Page 63

Pag.63 27/03/2014 8) n° 34 steam boiler time-out temperature alarm . Select drink steam not ready this alarm is visualised on display by code 34 cause: the steam boiler temperature has reached the minimum value of 105°c result: boiler heating is interrupted and the buttons of coffee-based, milk-base...

Page 64

Pag.64 27/03/2014 11) n° 38 steam boiler temperature alarm. Steam temperat. 38 this alarm is visualised on display by code 38 first case: the temperature inside the steam boiler has reached the limit value of 129°c (264.2°f) or more. Result: boiler heating is interrupted and all dose buttons are dis...

Page 65

Pag.65 27/03/2014 14) n° 63 clock error. Clock error 63 this alarm is visualised on display by code 63 solution: check the following: a) run down battery b) faulty master board 15) n° 65 motor block alarm. Motor block 65 this alarm is visualised on display by code 65 causes: a mechanical block occur...

Page 66

Pag.66 27/03/2014 this alarm is visualised on display by code 81 solution: check the following : a) check the power supply of the gsm modem installed in the coffee machine. B) check that the serial cable is properly connected in the gsm modem and in the master board (cn 16). 20) n°82 pin of the mode...

Page 67

Pag.67 27/03/2014 25) safety valve operation. No messages on the display cause: overpressure in steam boiler result: the safety valve opened at 1.7-1.9 bars, the steam is conveyed to the drip tray by means of a silicone tube. Cause: overpressure in the steam boiler or faulty safety valve. Solution: ...

Page 68

Pag.68 27/03/2014 special functions for machine calibration 1) calibrating the coffee dispensing pressure (pump pressure). To calibrate the coffee dispensing pressure use the device code a 0128 ( pic. A ). The procedure is the following : - replace the upper piston with the one equipped with pressur...

Page 69

Pag.69 27/03/2014 if the adjusting range is not wide enough to get the needed grinding degree, you can do the following: • remove the hoppers and/or product containers • remove the top cover from the machine (unscrew the 2 rear and 2 front screws) • unscrew the 2 screws ( pic.A ) and move the grindi...

Page 70

Pag.70 27/03/2014 recommendations for a correct preventive maintenance the aim of this schedule is to prevent as far as possible equipment from breaking down, through the periodical check-up and replacement of components subject to fair wear and tear, thus reducing service calls and relevant cost in...

Page 71

Pag.71 27/03/2014 d. Check at 12 months’ intervals same as points c1-22, plus replace the following: 1. Steam boiler safety valve 2. Coffee boiler expansion valve 3. Replace flat burrs grinder after having grounded approximately 300-500 kg of coffee for grinder with conical burrs, check and/or repla...

Page 72

Pag.72 27/03/2014 the essential brands group product you have purchased is subject to directive 2002/96/ec of the european parliament and the council of the european union on waste electrical and electronic equipment (weee) and, in jurisdictions adopting that directive, is marked as being put on the...