- DL manuals

- Airmaster

- Air Conditioner

- AM 100

- Operator's Manual

Airmaster AM 100 Operator's Manual

Summary of AM 100

Page 1

1 am 100 . 300 . 500 . 800 . 900 . 1000 . 1200 cv 80 . 200 dv 1000 1 . 2 . 3 operator’s manual.

Page 2

This manual must be read before using the airmaster air handling unit. Compliance with the manual ensures correct use of this product. When using the unit in a room with a fire or stove drawing air from the room, all applica- ble provisions must be observed. The unit should not be used in rooms with...

Page 3

3 table of contents 1. Airlinq ® ...........................................................................................................................................................5 2. Function principle ...........................................................................................

Page 4

4 5. Control functions ....................................................................................................................................... 24 5.1. Timer-controlled ventilation ...........................................................................................................

Page 5

5 10 9 8 12 15 4 5 3 11 2 13 7 14 6 1 10 9 8 12 15 4 5 3 11 2 13 7 14 6 1 1. Airlinq ® airmaster focuses not only on the air handling unit, but also on the control system software and operation. Airlinq is airmaster’s own unique ventilation control system, which gives the user and service technician...

Page 6

6 1 9 8 10 5 7 3 6 2 4 auto 3. Airlinq viva (white control panel) 3.1. Control elements 1. Air flow setting (blue light) using a touch sensitive control area, see page 8. 2. Function button (manual start, manual stop, manual temporary stop), see page 7. 3. Usb mini-b port. To set or programme the ai...

Page 7

7 1. Auto 2. 3. 1. Start or restart automatic operation. Press the function button. >> the unit will start according to its programming if a start signal is active. The control system will reactivate automatic operation after manual override. The current air flow will be shown by a blue stripe. “aut...

Page 8

8 _ + auto auto auto 3.2.4. Air flow - manuel setting drag your finger on the setting area clockwise to increase air flow or counter clockwise to reduce air flow. The light will follow your movement. Lift finger from the area when the required air flow is shown. The cur- rent setting will then be sh...

Page 9

9 auto auto auto 0 2 2. 1. 3. 4. 4 6 8 3.2.5. Holiday mode - activation holiday mode is used as basic ventilation when the room is unused for an extended period, e.G. Holidays. In holiday mode, the air handling unit will run with min. Air flow. The internal control function “low temperature” is acti...

Page 10

10 warning (yellow) the air handling unit remains in operation in the event of a warning, but can deviate from standard operation. 1. Slow flash: condensate - there is condensate in the cooling module which has not been automatically removed. Module out of operation. • remove condensate manually fro...

Page 11

11 1 6 8 3 7 4 5 2 9 “selectable” “selected”. “increase” value. “reduce” value. “holiday mode” symbol shows for holiday mode instead of fan symbol (pos. 7.), see page 24. Padlock shows when operated with active automatic operating lock and active screen lock. "auto" “automatic operation” text off wh...

Page 12

12 _ + auto auto auto 4.2.2. Air flow - manuel setting drag your finger on the setting area clockwise to increase air flow or counter clockwise to reduce air flow. The light will follow your movement. Lift finger from the area when the required air flow is shown. The current setting will then be sho...

Page 13

13 4.2.3. Automatic operation auto automatic operation is started using a timer, night time cooling, sensors, external contacts or an analogue bms system. The current air flow and text “auto” are shown on the control panel with a blue light above the fan symbol. Read also “control functions” on page...

Page 14

14 4.2.4.2. Off press menu field “ off” >> the control panel will show “shutdown? Afterwards the system has to be started manually.”, a tick for “confirm” or a cross for “cancel”. Press the tick to switch off. (the unit must then be started according to sect. ”start and standby” on page 13. Press th...

Page 15

15 operation started by operation start signal - “external”, using external contacts and relays. - “airlinq”, manual start using a control panel. - “co2”, using a co2 sensor. - “pir”, using a passive infrared sensor. - “bms”, using an analogue or digital bms system. - “timer”, using a timer. - “holi...

Page 16

16 hardware the condition of the individual components are monitored and displayed in this menu. Component functional = “ok” component with fault = “fault” component not programmed = “n/a” components monitored: room temperature room temperature sensor. Inlet temperature inlet temperature sensor. Out...

Page 17

17 4.2.4.5. Setup all operational parameters can be changed under the “ setup” menu, according to local conditions. Timers timer-controlled ventilation and night time cooling, set using the control panel or “airlinq user tool”, starts and stops the air handling unit using a timer. There are up to 7 ...

Page 18

18 adjust or add a program: after selecting the program to be adjusted, or use of the function button “add” (see program view on previous page), ‘setting’ mode will start. Mo tu we th fr sa su timer-contr. Ventilation start flow % temp °c stop 08:15 16:30 80 18 increase/reduce a value: values can be...

Page 19

19 date and time date and time are preprogrammed according to the calendar. Time changes automatically to summer and winter times. The summer/winter setting can be deactivated using the airlinq service tool. The control system software date and time synchronises automatically with date and time on a...

Page 20

20 startup guide the startup guide starts automatically when the unit is started for the first time. The guide can also be started manually subsequently (menu under “setup”), e.G. To retro- install a co 2 sensor. The most important settings can be made using the startup guide. The guide must be run ...

Page 21

21 n auto auto 4.2.6. Airlinq bms when using airlinq bms with up to 20 air handling units and 20 cooling modules, the system is usually broken down into several groups (g) with at least one unit (id) each, with all units in a group controlled uniformly. One of the units in a group will be programmed...

Page 22

22 control and setting each group in the system is controlled and set in the same way as an individual unit. That means that all control options are available for all groups. The status menu and alarm view are available for all individual units. A group or single unit can be selected for each screen...

Page 23

23 4.3. Warning and alarm in the event of warnings and alarms, a triangle with an exclamation mark in its centre with a yellow or red light (pos. 4 under ”control elements” on page 11) will show in the top left hand corner of the control panel main screen. Press the symbol. >> the control panel will...

Page 24

24 5. Control functions 5.1. Timer-controlled ventilation this function controls the airmaster unit fully automatically according to a timer using an integrated clock. Timer-controlled ventilation can be set using the control panel menu or airlinq user tool. This function has 7 independent programs ...

Page 25

25 0 a a+10% b min max min+x 0 0 a min max 0 b 5.6. Control using a co 2 sensor a co 2 sensor is used to control the air handling unit inde- pendent of the room’s co 2 level. The air flow can either be (1) controlled by the co 2 sensor, or let the unit’s complete operation be (2) controlled by the c...

Page 26

26 5.7. Boost the boost function can adjust the airflow temporarily and is programmed to use some fixed control voltages for the supply fan and the exhaust fan respectively. It is possible to adjust the control voltages for the fans independently of each other if unbalanced ventilation is required. ...

Page 27

27 6.3. Virtual preheat virtual preheat ensures unit operation (along with the preheat process) at low outside temperatures for the cv 80, am 100, cv 200, am 300 and dv 1000 units. It can operate in two different modes: “comfort mode” as standard and “green mode” as an option. Settings are made usin...

Page 28

28 7. Service and maintenance service and maintenance are vital for problem-free opera- tion of an airmaster unit and its equipment. The majority of servicing consists of cleaning and inspection of the condensate system and filter change. We recommend that all service is performed by authorised expe...

Page 29

29 7.4. Filter change all filters in the air handling unit (incl. Cooling module) are monitored by the unit’s filter monitoring system. The filters must be replaced when the monitoring system indicates a filter change, but at least annually. Filter monitoring can be adapted to local conditions using...

Page 30

30 7.4.3. Filter change for cv 80-200, dv 1000, am 100, 300, 500, 800, 1000 these units are fitted with an exhaust air filter (m5 only) and one or two fresh air filters (m5, f7, f9) unless fitted with a cooling module, in which case the air handling unit will only have one exhaust air filter. Nb! Dv...

Page 31

31 retaining plate for fresh air filters (1) under exhaust air filter. Am 100, cv 80, cv 200: supply air filter (1) and exhaust air filter (2) under epp covers. Dv 1000: supply air filter (1) and exhaust air filter (2) under a cover (3). 1 2 3 3 7.4.4. Filter change am 900 and am 1200 nb! When chang...

Page 32

32 filter position am 900: 1. Supply air filter (1) (m5, f7, f9) behind the service cover on top of a am 900 unit: 2. Extracted air filter (2) (m5 only) on top of the front cover on a displacement model: 3. Extracted air filter (2) (m5) at the bottom of the front cover of a mixing model: filter posi...

Page 33

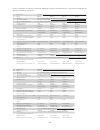

33 195 x 185 x 92 195 x 185 x 92 195 x 185 x 92 195 x 185 x 92 344 x 220 x 65 344 x 220 x 65 242 x 220 x 92 242 x 220 x 92 280 x 220 x 47 280 x 220 x 47 240 x 440 x 47 280 x 220 x 47 380 x 340 x 47 470 x 300 x 47 190 x 340 x 47 470 x 300 x 47 560 x 284 x 47 470 x 300 x 47 420 x 408 x 92 325 x 480 x ...

Page 34

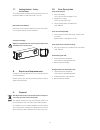

34 7.6. Setting inlet opening am 100, 300, 500 and 800 the inlet opening louvres can be bent slightly using long- nosed pliers to adjust inlet direction. Am 900 the inlet opening area can be adjusted and fixed at the top of the front cover using a cover plate. • switch off the air handling unit. • d...

Page 35

35 7.7. Cooling module - safety instructions the cooling module is exempt from the directive for pressure equipment (ped) according to article 1, part 3.6. Maintenance and repair maintenance can be performed by the end user, but repairs must be performed by authorised experts. Transport/storage nb! ...

Page 36

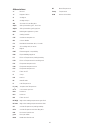

36 abbreviations % percent °c degrees celsius a analogue ai analogue input am airmaster air handling unit aqc l airlinq controller, type l, black box aqc p airlinq controller, type p, grey box bms building management system cc cooling module cdt condenser temperature co 2 carbon dioxide cv residenti...

Page 37

Auto _ + quick guide viva quick guide airlinq viva warning and alarm. Flashes/constantly yellow for warn- ings and red for alarms. See operator’s manual page 9. Cancel automatic operating lock. Press current air flow for at least 1 second. Set air flow. Press current air flow and drag with finger to...

Page 38

_ + auto quick guide orbit quick guide airlinq orbit warning and alarm. Yellow for warnings and red for alarms. See operator’s manual page 22. Set air flow. Press current air flow and drag with finger to desired air flow. Or press direct on the desired air flow. Co 2 level symbol (shows with active ...

Page 39

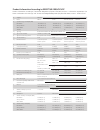

39 a) b) c) -78,1 kwh/(m² ·a) -40,7 kwh/(m² ·a) -16,7 kwh/(m² ·a) a -79,6 kwh/(m² ·a) -41,7 kwh/(m² ·a) -17,3 kwh/(m² ·a) a -80,8 kwh/(m² ·a) -42,5 kwh/(m² ·a) -17,9 kwh/(m² ·a) a+ -80,9 kwh/(m² ·a) -42,6 kwh/(m² ·a) -18,0 kwh/(m² ·a) a+ d) e) f) g) 81 % 82 % 84 % 84 % h) 0,026 m³/s @ 10 pa 95 m³/h ...

Page 40

40 a) b) c) d) e) f) 82 % 82 % 84 % 90 % g) 0,060 m³/s 216 m³/h 0,110 m³/s 396 m³/h 0,167 m³/s 600 m³/h 0,173 m³/s 623 m³/h h) 0,06 kw 0,12 kw 0,11 kw 0,17 kw i) 1040 w/(m³/s) 0,289 w/(m³/h) 1011 w/(m³/s) 0,281 w/(m³/h) 664 w/(m³/s) 0,184 w/(m³/h) 638 w/(m³/s) 0,177 w/(m³/h) j) 1,0 m/s 0,8 m/s 1,0 m...

Page 41

41 p rated [kw] 0,6 2,5 3,3 p rated [kw] p eer [kw] 0,1 0,6 1,0 p cop [kw] eer d [-] 4,0 4,0 3,2 cop d [-] p to [w] 0 0 0 p sb [w] 0 0 0 q dd [kwh/a] 50 214 364 l wa [db(a)] 42 42 44 gwp [kg co2 eq.] 1430 1430 2088 p rated [kw] 5,2 6,5 p rated [kw] p eer [kw] 1,1 1,5 p cop [kw] eer d [-] 4,7 4,5 cop...

Page 42

42 ec declaration of conformity manufacturer airmaster a/s industrivej 59 dk-9600 aars denmark herewith declare that the following air handling unit / cooling module (series and type (serial numbers) product cv 80 and am 100 (3102501-3199999), cv 200 (3201081-3299999), am 300 (0704474-0799999), am 5...

Page 43

43.

Page 44

13896 © v ersion 6.1 - 201 6-09-19 industrivej 59 tel: +45 98 62 48 22 info@airmaster.Dk dk - 9600 aars fax: +45 98 62 57 77 www.Airmaster-as.Com denmark.